Using the best ender 3 nozzle and nozzle size for your print job is crucial for a perfect and polished print. Doesn’t matter if you are a beginner or an experienced 3d printing nerd you must know about all the nozzle options available in the market and all the different sizes. Knowing about them and their advantages and disadvantages will always help you choose the right nozzle for your print job additionally it will help you to avoid print fails and errors.

The default 0.4mm is the best nozzle size for the majority of the prints unless you have specific printing needs, all you have to do is make sure it’s clean after every print so it doesn’t clog, and keep changing it after every 6-12 months depending on the runtime. If you want a super detailed print go for a smaller nozzle that has a small bore diameter, something like a 0.25mm nozzle would be great. If you want to print faster then go for a larger nozzle, according to my experience I would suggest you go for a 0.6 mm nozzle which can preserve some of the print details like 0.4mm with the right settings.

Choosing the right nozzle material is also very simple, brass nozzles are the best choice if you want to print only PLA, ABS, or PETG. If you want to print other abrasive materials sometimes then stainless steel will be fine, and hardened steel nozzles are the right choice for those who want to print abrasive materials most of the time. To get a better clarification about each nozzle type and size you must read the rest of the article because I’ll cover each nozzle material and size in detail.

Contents

Ender 3 hotend and nozzle

Before we go further and discuss all the different possible nozzle sizes and materials, let’s understand the stock Ender 3’s hotend and nozzle. The stock Ender 3 is equipped with the MK8 hotend with M6 threading which supports 1.75mm filaments. So when choosing keep in mind that the nozzle thread/throat must be m6 otherwise it won’t fit in the hotend.

The stock Ender 3 comes with the industry standard 0.4mm brass nozzle. The reason 0.4mm is the default and not something else like 0.5 or 0.3 is because 0.4mm nozzles are the perfect balance between print speed and print quality. With larger nozzles, you might face problems like stringing and extruder skipping and with smaller nozzles, you will face frequent clogging of nozzles. 0.4 is the sweet spot that gives perfect quality, fewer clogs along with good print speed.

Because of properties like high thermal conductivity, machinability, and sufficient wear resistance brass is used as the standard metal for 3d printer nozzles. With brass nozzles, you can print filaments like PLA, ABS, and PETG for months without any problems although doing regular maintenance of your Ender 3 is essential. For working with abrasive filaments like

Best Nozzle Size For Ender 3

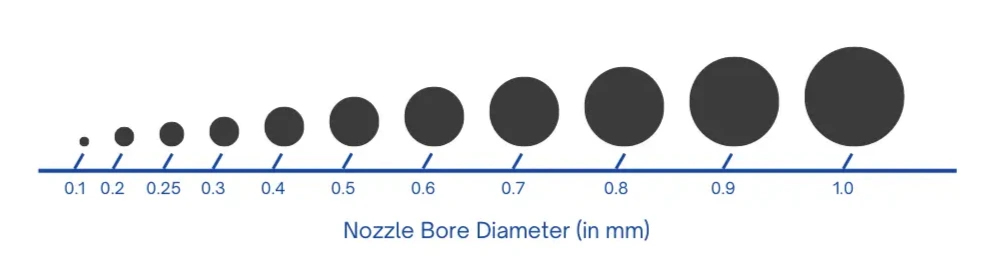

Nozzle size or ‘bore diameter’ is the output diameter of your nozzle, it decides how and how much of your 1.75mm filament should be extruded. The market offers a wide range of nozzles with different nozzle sizes ranging from 0.1mm to 1.0mm. However, in the 3d printing industry, 0.4mm is considered the standard size for 3d printers, including the Ender 3. Since 0.4mm is the industry standard, any size below 0.4 is considered small similarly any size above 0.4 is considered large. Smaller nozzles come with their own set of advantages and disadvantages, and so do the larger nozzles.

As I’ve stated already the best nozzle size for Ender 3 is the widely used standard 0.4mm. However, if you want to achieve a specific task with your printer nozzle then it’s worth looking at other size options as well

Smaller Nozzle size

Nozzle sizes smaller than 0.4mm are categorized as smaller nozzles, 0.1, 0.2, and 0.3 are widely available in the market while the most used small-sized nozzle is 0.25. Smaller nozzles capture more details on the print as compared to the standard and the larger nozzles, as you increase the nozzle size you will start losing the minute details. If your print demands high detail and accuracy you must go with smaller nozzles.

Advantages

- High resolution: With smaller nozzles, you can print with smaller layer heights, for a 0.25mm nozzle you can set the layer height as low as 0.06. Smaller nozzles also help to achieve higher xy resolution, although you will get a point where the quality returns are diminishing unless you are printing something very niche like miniatures.

- Thin supports: You will get very thin supports when printing with smaller nozzles, which are easier to deal with while removing them from the final prints. Thin supports are less likely to affect the final quality of the print.

- Subtle layers: Because of the fine details achieved when printing with smaller nozzles, the layer lines are not “visible”. Layer lines being less visible makes the final prints look smoother and polished.

Disadvantages

- Slower prints: The main disadvantage with smaller nozzles is the time it is required to print an object. With smaller layer heights, your Ender will need to print more layers as compared to the standard nozzle size which significantly increases the print time.

- Nozzle clogs: This is not only a disadvantage but I consider this a problem. Smaller nozzles tend to clog a lot also, unclogging smaller nozzles is painful. if you are running a smaller nozzle that keeps clogging then I would suggest you replace the nozzle with another one.

- Filament compatibility: Generally speaking, you won’t have much trouble printing materials like PLA, ABS, and PETG except for nozzle clogging. However, in the case of filled composite filaments, the story is quite different because these materials contain particles that are not melted when they are passed through the hotend. A larger nozzle could pass them easily because of the larger bore diameter but a smaller nozzle will struggle to do so.

Larger Nozzle Size

Any nozzle size larger than the standard 0.4mm is considered a large nozzle, just like the small nozzles these also come in various sizes starting from 0.5 to all the way up to 1.0mm. The real question is do you really need a 0.8mm or 1.0mm nozzle? if your print doesn’t need any solid detail then you can go with them as prints produced by these nozzles will definitely lack details, also the layer lines will be more prominent.

Advantages

- Faster prints: With the larger nozzles you can print with greater layer heights, which lets your printer finish the job in comparatively fewer cycles. So, if time is a constraint for you then larger nozzles will definitely help out in the exchange of print quality.

- Less clogs: Larger nozzles aren’t very likely to clog, they can run for a longer time without clogging. The small particles or debris that clog the smaller nozzles can easily pass through these bigger nozzles. Keep in mind that if you are not maintaining your Ender 3, larger nozzles can also clog, it’s just a matter of time before the gunk gets big enough to clog the nozzle.

- Strong prints: Generally larger nozzles also provide stronger prints because of more surface area between each layer resulting in better adhesion.

- More material choice: Along with common materials like PLA, ABS, etc. you can also print filled composites with larger nozzles without much problems unless it’s a brass nozzle.

Disadvantages

- Less resolution: Of course, the most common disadvantage is larger nozzles print fast but at the cost of fine details of the print. There are 2 factors that lead to less detailed print, the first one is the layer height and the second one is print speed, high print speed combined with more filament flow leads to less accuracy of the print.

- Thick supports: A larger nozzle size will print thick supports, which are more difficult to remove as compared to think supports. Also, they are more likely to leave it’s impression on the final print as compared to smaller nozzles.

- Layer lines: When you are printing with a larger nozzle the layer height will also be high compared to standard and smaller nozzles. The higher the nozzle height, the more visible layer lines. To minimize the layer lines you can reduce the layer height, but again it will increase the print time.

- Hotend Limitation: There is one more catch with larger nozzles the stock Ender 3 hotend might not be able to keep up with the flow rate of a large nozzle which will lead to problems like extruder skipping, to tackle this problem you can replace either the default hotend with a all metal hotend or you can replace only the heat break.

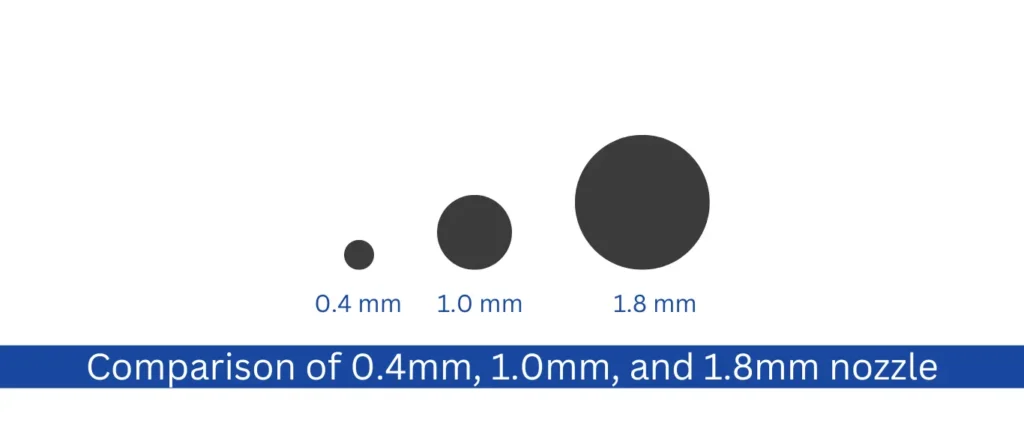

CHT Nozzle

For some reason, if you want a nozzle with a bore diameter larger than 1.0mm then BondTech CHT nozzles have got you covered. The CHT(Core Heating Technology) nozzles by BondTech starts from 0.6mm and goes up to 1.8mm, the filament itself is 1.75mm while the output diameter or bore diameter of the nozzle is 1.8mm. The way they are able to achieve this is by splitting the filament into 3 different paths when it enters the nozzle and those 3 different paths combine just before the tip of the nozzle making it possible to output 1.8mm.

However, with such a large nozzle the stock hotend won’t be able to keep up and will start skipping and stringing with many other problems. To use nozzles like 1.8mm CHT you must replace the regular Ender 3 heat break with a bimetallic heat break for better heat supply to the filament, alternatively, you can also replace the regular Ender 3 hotend with an all metal hotend for an overall better performance.

Ender 3 Nozzle types

The most commonly used in the manufacturing of 3d printer nozzles is brass, brass is an alloy of copper and zinc, and it exhibits properties like great heat transfer, corrosion resistance, and machinable which makes it highly suitable for 3d printing. For most of the 3d printing jobs brass nozzles will just do fine unless you have specific requirements that can be better suited for nozzles that are made of different metals to achieve those tasks.

The metal or substance used to manufacture the nozzles is the most crucial factor because the material carries its all physical and chemical properties like heat transfer, wear resistance, corrosion resistance and so on to the manufactured nozzle. Each nozzle that comes with a different material has its own set of pros and cons which plays important role at the time of using them and printing.

Brass

When it comes to 3d printer nozzles brass is considered the standard because of its properties like corrosion resistance, good thermal conductivity, and inexpensive which makes it the perfect choice for a 3d printer nozzle. However, brass nozzles are not as wear-resistant as other nozzles present in the market. Because of their less wear-resistant property, they don’t last long as compared to other nozzles. If you are not printing abrasive materials then they typically last for 6-12 months depending on the runtime, and if you print abrasive materials then the nozzle will wear out really quickly like 3-6 months again depending on the runtime it can be moer or less.

Buying link: Regular brass nozzle set

Max temperature: 300°C

Best for: PLA, ABS, PETG, Nylon, TPE

Stainless steel

Stainless steel nozzles are more wear-resistant compared to brass nozzles however, they are less thermal conductive so they take more time to achieve the target temperature. What makes stainless steel nozzles unique and niche is that they are food-safe, while brass nozzles may contaminate the prints with lead which certainly makes them unsafe for food related use cases and prints. If your primary objective is printing food-safe items then stainless steel nozzles will be the best choice for you.

Buying link: Stainless steel nozzle

Max temp: 500°C

Best for: NylonX, Carbon fiber, Glow in the dark, Metal filled, Wood filled, Ceramic filled

Hardened steel

Hardened steel nozzles offer even more wear resistance compared to stainless steel nozzles, however, they tend to be even less thermally conductive which in turn takes for the nozzle to reach target temperature. But how wear-resistant they are? Well, you can run abrasive filaments through these nozzles for years and for normal filaments, they will last even longer. One drawback of these nozzles is that they have slightly rough internal texture which can reduce your print quality.

Another thing is that they are quite costly, but they last forever even if you print only abrasive materials which I think justifies the price point because if you use brass for printing abrasive materials you will have to keep changing the nozzles causing you money and unnecessary trouble. Hardened steel nozzles are also available in several varieties like blackened, copper, nickel plated, etc.

Buying link: Hardened nozzle

Max temp: 500°C

Best for: Heavy use of abrasive filaments

Assembled nozzles

Assembled nozzles are not made up of only one metal or material, rather two different parts of a nozzle are created using two different materials and then they are assembled to make the nozzle. The problem that we saw with the other materials that is either a nozzle will have high wear resistance or high thermal conductivity and to balance out both of these properties assembled nozzles can be utilized.

The main body of the assembled nozzles has high thermal conductivity, while the inner path or the tip of the nozzle will have high wear resistance. The high thermal conductivity of the body of assembled nozzles ensures continuous heat transfer from the heat block to the filament, also the nozzles reach their target temperature relatively quickly. The high wear resistance of the tip and the internal of the nozzle keeps the nozzle running for a longer time, unlike brass nozzles.

Assembled nozzles are high priced, a stock Ender 3 won’t be able to utilize these nozzles to their full potential if you have an upgraded Ender 3 or want to print at very high temperatures then you can go for these nozzles. Assembled nozzles come in different variations like ruby and sapphire.

Buying link: Ruby tipped nozzle, Diamondback nozzle

Max temp: Generally high, however, varies with the material used in the nozzle assembly.

Best for: Engineering plastics like PEEK, Ultem

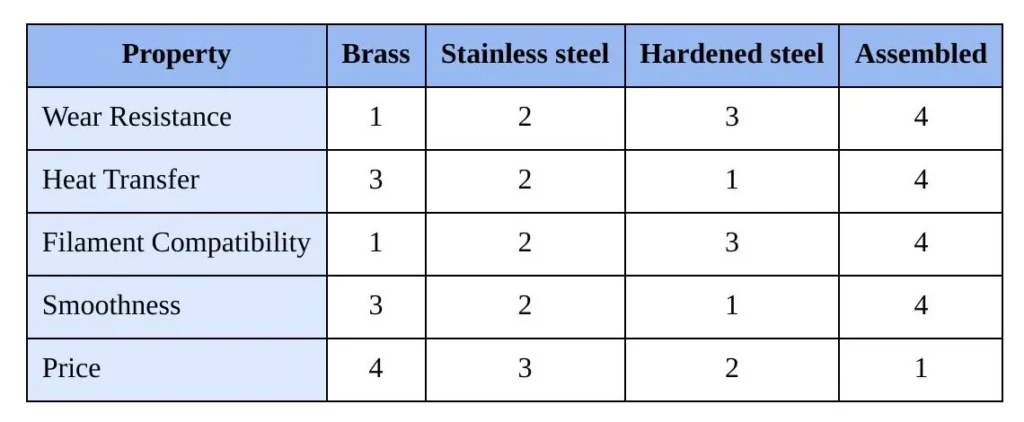

Nozzle Material Comparison

This is how I would rank each of these nozzles based on certain use cases or properties, my rankings are not absolute nor do they represent any data. I’ve ranked them based on my research and observation. Also, the below rankings may change for you based on the quality of the nozzle, their composition, and the manufacturing process however for the majority of the nozzles you can use the below table for reference.

What is the best Nozzle for Ender 3?

I would say regular 0.4mm brass nozzles are the overall best for hobbyists because they are suitable for a wide variety of prints at a very minimal cost.

However, if you want to print materials like glow-in-the-dark, wood filaments, and carbon filaments, especially metal ones then hardened steel nozzles will be your best friend.

If your most prints will need PLA like non abrasive filaments but sometimes you want to try abrasive materials then stainless steel will be the right choice.

Premium nozzles like diamondback and ruby-tipped are the best at printing every material, they last forever and they have amazing heat transfer which is very tempting but their price point might hold you back.

Conclusion

Choosing the right nozzle and the right nozzle size can be difficult especially if you are a beginner, with this article I’ve shared every piece of knowledge that I’ve gathered over the years in 3d printing to help you better understand the nozzles.

If you need detailed prints go for a smaller nozzle size like 0.25mm, if you need faster prints for something larger like 0.6mm, and if you need a balance between both then go for the standard 0.4mm nozzle.

If you plan to print materials other than the standard ones like PLA, ABS then going for a hardened steel nozzle will be perfect. However, if you are feeling rich then you can go for premium nozzles like diamondback and ruby-tipped.

If you are still confused you can pass the questions from your mind to the comment box below.